A manufacturer of profiles in thermoplastic material asked the Perimetra team to assess conformity status of 5 extrusion lines installed in their factory. Some lines proved to be self-assembled and without CE marking, others had undergone revamping intervention over time by adding and substituting components which altered machinery performance.

Such interventions require new CE marking of the line as per machinery directive and pertinent current standards and regulations

Need for interventions to increase safety level and the absence of conformance with standards and legislations exposed the company to risks which could possibly compromise their business continuity.

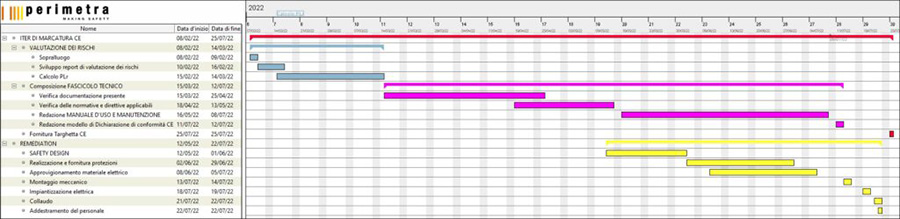

The process lasted 6 months with an active presence of Perimetra CMSE® – Certified Machinery Safety Expert engineers who considered all the necessary steps to carry out the project.

1 ) Perimetra risk assessment

All extrusion lines were examined whilst working, and particular attention was given to mechanical movements, stopping time and tasks carried out by machine operator, to identify and analyse risks according to the requirements set out in UNI EN ISO 12100 standard.

A number of non-conformities were detected, then all procedures to carry out to increase safety level were provided, by employing the latest technical standards, and to meet the pertinent E.R.H.S (Essential Requirements of Health and Safety) as per Machinery Directive 2006/42/CE.

2) Perimetra Safety design

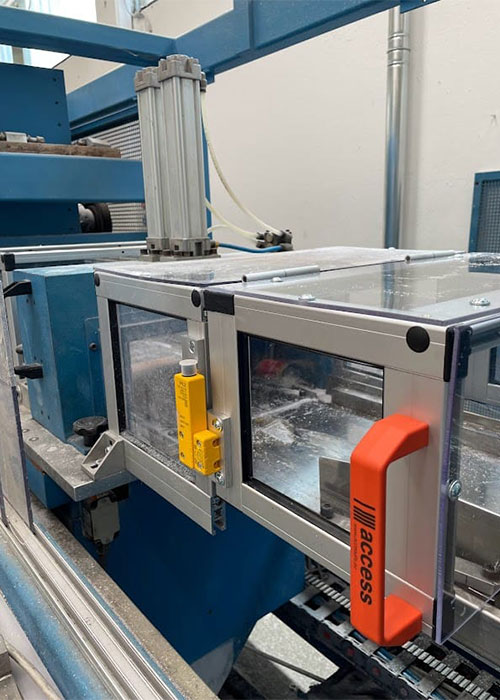

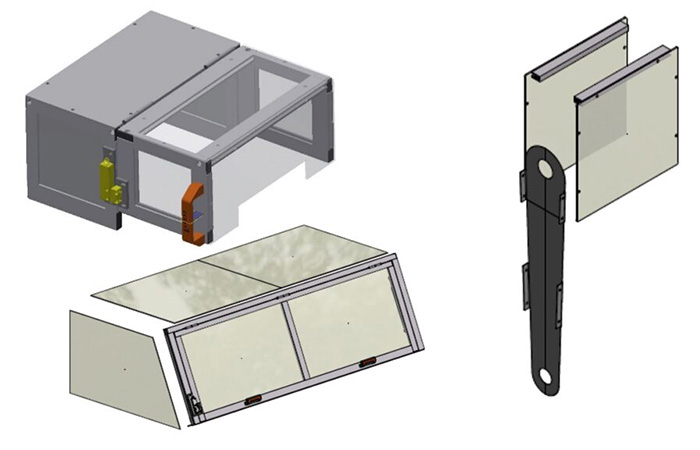

All interventions were on-board machinery, so our engineer specialised in aluminium products, after an accurate on-site inspection, designed and realised the suitable safety guards to reduce the presented risks.

3) Perimetra Remediation

Safety remediation to include installation of on-board machinery safety guards, safety sensors, safety logic development and personnel training regarding safety procedures, for example, cutter stop when safety guard is opened.

4) Perimetra CE marking process

Perimetra has compiled all the instruction and maintenance manuals of the 5 extrusion lines and has provided support to draft the technical file according to current standards and regulations, including the form of CE declaration of conformity and relative CE plate.

Focus on machinery safety

By realising this project, Perimetra has secured the machinery guaranteeing full conformity with all applicable Directives with reference to a number of technical standards among which:

Type A standards:

- UNI EN ISO 12100– Risk assessment and risk reduction

Type B standards:

- UNI EN ISO 14120– General requirements for fixed and movable guards

- UNI EN ISO 13849– Parts of command systems connected to safety

- UNI EN ISO 20607 – Instruction handbook — General drafting principles

Type C standards :

- UNI EN 1114-1– Extruders safety requirements

- UNI EN 1114-3– haul-offs safety requirements

All risks connected to the machinery have been reduced still maintaining factory full operation and productivity.