CE marking process – slitter lines

Risk assessment and securing of slitter lines to achieve CE marking, as per Machinery Directive 42/2006.

Die Accessafe-Sicherheitslösungen in Betrieben

Risk assessment and securing of slitter lines to achieve CE marking, as per Machinery Directive 42/2006.

Realization of machinery side protection systems and safety logics for pump testing benches.

Analysis and safeguarding of a TNT non woven fabric production line to achieve CE marking conformant with Machinery Directive 42/2006.

Analysis, design and safety upgrade Safety of milling machines in annex V of Dlgs 81/2008 for the production of hydraulic pumps

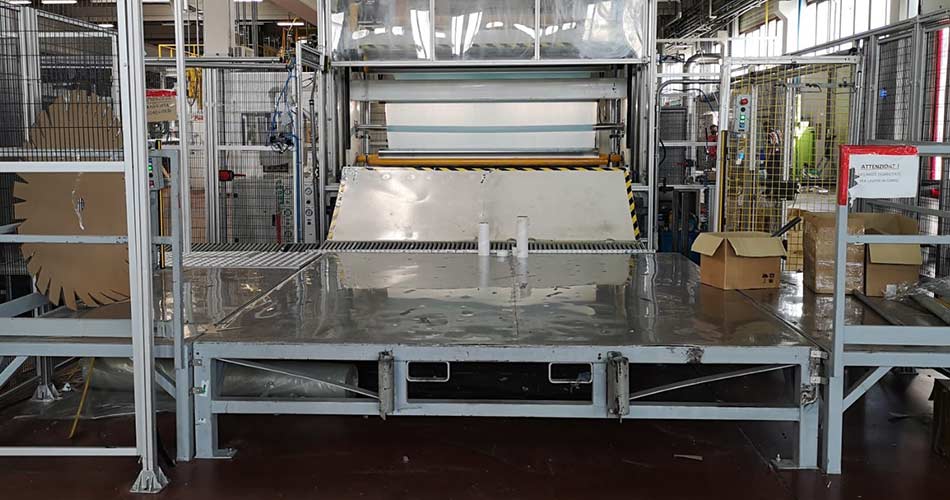

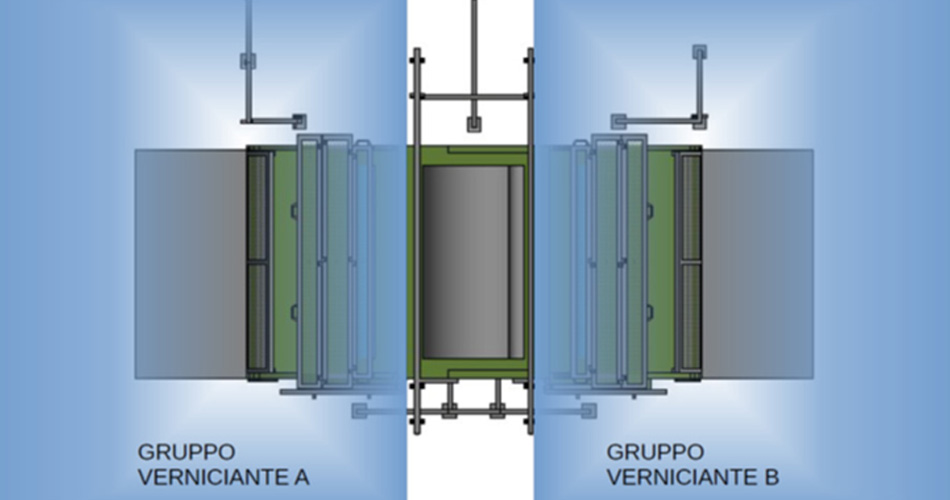

Remediation of varnishing heads in a coil processing line according to annex V Dlgs 81/2008. ATEX environment.

Safety upgrade of a drawing line according to Machinery Directive 2006/42/CE

Press feeding device safety upgrade according to annex V Dlgs 81/2008

Remediation project according to annex V D.lgs 81/2008 of a coated coil cut-to length line

Upgrade according to annex V Dlgs 81/2008 of a galvanized coil cut-to length line

Accessafe was commissioned to develop a safety upgrade project on a coating head machine, which the commissioning company had made available to the workers at their factory.

Accessafe was commissioned to develop the project to secure nine injection moulding machines for thermoplastic moulds with associated unloading automation.

Carcano Antonio SPA assigned ACCESS the project to develop the safety system for a new part of their production plant to be integrated with the pre-existing one.