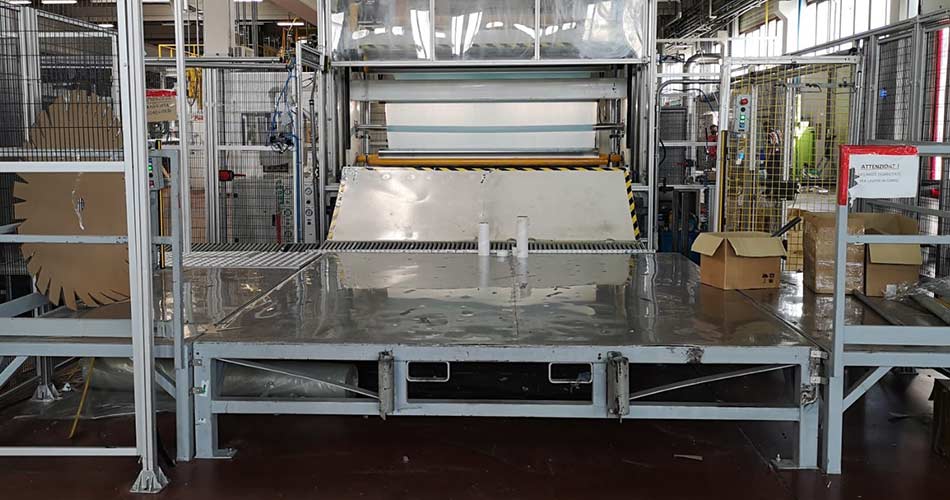

Carcano Antonio SPA assigned ACCESS the project to develop the safety system for a new part of their production plant to be integrated with the pre-existing one.

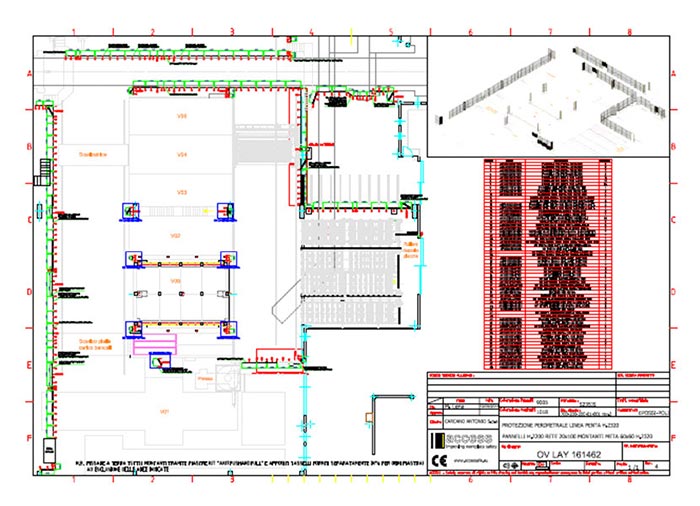

Risk analysis and the new plant manufacturer’s technical specifications were passed on to Access’s engineers for the lay-out design with pertinent access control which respected PLr (as per UNI EN ISO 13849:2016).

Risk analysis and the new plant manufacturer’s technical specifications were passed on to Access’s engineers for the lay-out design with pertinent access control which respected PLr (as per UNI EN ISO 13849:2016).

Indeed, the company’s production process is entirely integrated and traceable from raw materials to end-product as required by GMP, UNI EN ISO 9001:2008 and UNI EN ISO 14001:04 standards: an example of quality and efficiency to assure customer satisfaction and environment protection.

The order, which consisted of both the supply and mounting of the mechanical part and the supply of material, installation and cabling to the plant, was processed along with the scheduling of mechanic and electric technical staff intervention for a total of 8 working days from the material delivery date and for a total of three weeks from project acceptance.

The order, which consisted of both the supply and mounting of the mechanical part and the supply of material, installation and cabling to the plant, was processed along with the scheduling of mechanic and electric technical staff intervention for a total of 8 working days from the material delivery date and for a total of three weeks from project acceptance.

Functional tests were carried out at the end of set-up in the presence of the plant manufacturer and Carcano technicians, followed by the handing over of all documentation relative to certifications, instruction and maintenance manuals and technical data sheets.

The executive project Functional Safety

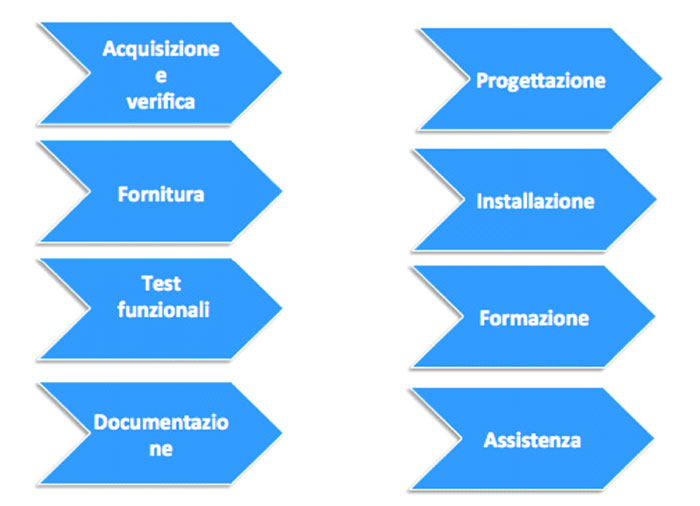

The executive design Functional Security Perimetra was developed according to the block diagram characteristic of this innovative service of Access, which is also available to customers in a partial manner: Acquisition and verification of risk and RES analysis, Executive design of the perimeter protection system, Supply of mechanical and electronic components, Installation and wiring, Functional testing, Training, Release of technical documentation, Scheduled after-sales support.

Regulatory insight from Marco Vaccarone CMSE® Certified Machinery Safety Expert Functional Safety Manager

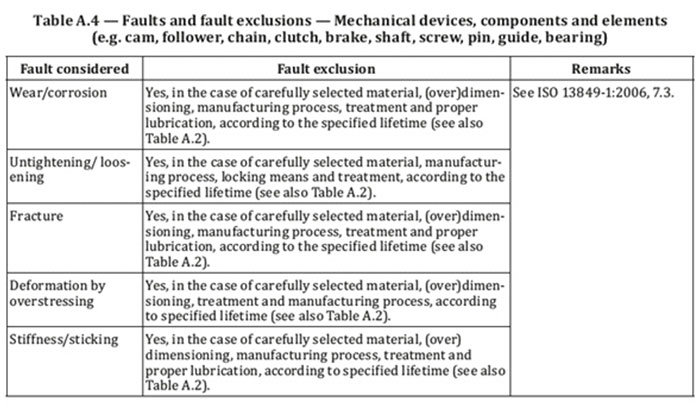

During the review of the specifications resulting from the manufacturer’s risk analysis delivered to us for the evaluation and development of the securing project, I was able to collaborate with the engineers who had developed it because there was a risk consideration to the achievement of PLr that could have subjected the related certification to litigation. The required PL was equal to «d,» and to achieve it, an electro-lock with a latch system for mechanical failure exclusion was planned: guaranteeing this performance would have resulted in the manufacturer having to demonstrate that it had complied with the failure exclusion requirements of UNI EN ISO 13849-2:2013 (Table A.4) and that the maximum actuator engagement speed required by the device manufacturer would not be exceeded under any circumstances.

In view of this consideration, it was decided to modify the design by applying electro locks and sensors with transponder technology to ensure the achievement of PLr without fault exclusion.