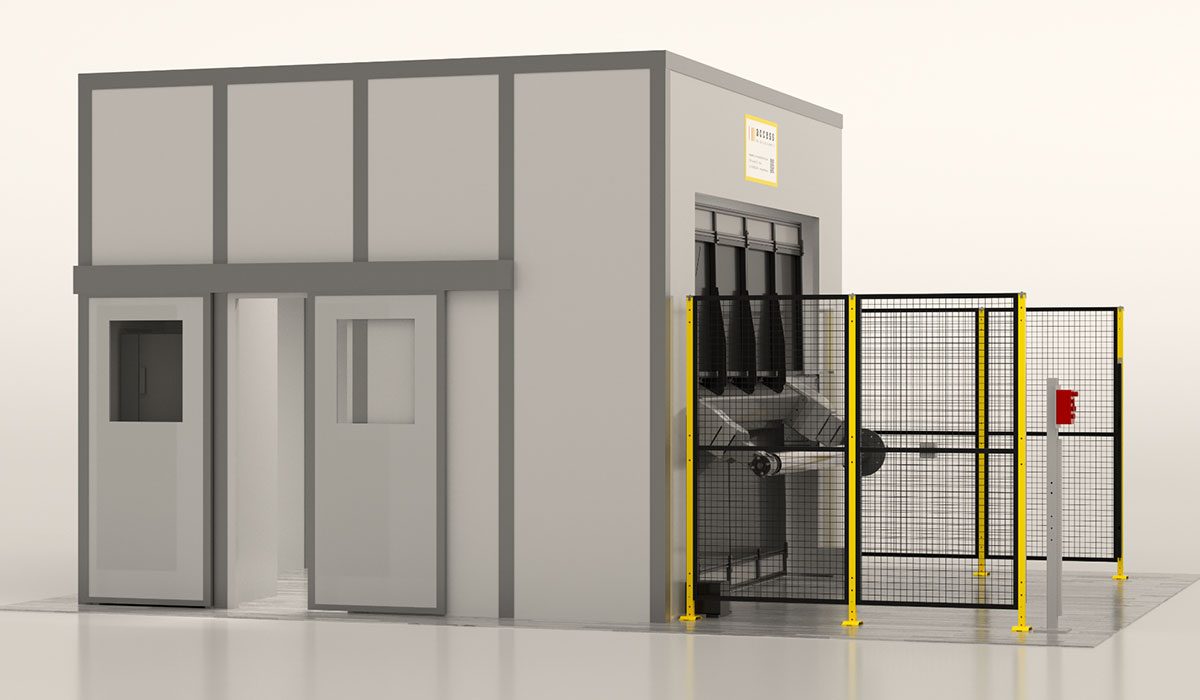

The industrial design applied to Accessafe enclosures is aimed at enhancing machinery technological content and employs all available materials to optimize functionality and aesthetics. Accessafe enclosure is a modular systems which can act as a protection casing, noise reduction system, emission management, operator cabin and laser containment.

Modular engineering allows for quick design, industrial production, standard logistics delivery and availability of spare parts from our catalogue. Installation comes with CE certification as per Machinery Directive and other relevant directives along with technical documentation, technical files, operator and maintenance manual and detailed assembly instructions.

Accessafe enclosures can be perfectly integrated with all other Accessafe products such as high-speed doors, modular protections and access control systems, light, ventilation and functional and safety command panels.

SELF-SUPPORTING SHEET METAL PROTECTIONS FOR ROBOTS

The reduction in the operating space of industrial robots and the increasingly frequent use of standardized islands has required us to design modular, multi-purpose protection systems that integrate the function of safety shielding with that of fume, 3D laser beam, noise, and lighting containment.

Accessafe manufactures self-supporting sheet metal guards that enhance technology through aesthetics.

Our Technical Department creates perfect functional integration with all the structural elements of the systems in accordance with Machinery Directive 2006/42/EC and applicable standards, putting operator safety first by protecting against accidental projections of materials being processed, the use of 3D laser equipment, and harmful emissions.

As with all Accessafe products, ease of assembly and disassembly is guaranteed to ensure rapid maintenance and packaging management with modular crates to enable efficient component logistics.

SCOPE OF APPLICATION

- Robots and automation

- 3D lasers

- Welding islands

COMPATIBILITY

- HSRS series high-speed doors

- Perimeter protection

- Access control systems

- Functional and safety control panels

REGULATIONS

- Machinery Directive 2006/42/EC

- EN 1090-1: 2012 Execution of steel and aluminum structures

- UNI EN ISO 12100:2010 Safety of machinery – General principles for design – Risk assessment and risk reduction

- UNI EN ISO 14120:2015 General requirements for the design and construction of fixed and movable guards

- UNI EN ISO 13857:2008 Safety of machinery – Safety distances to prevent

- access to dangerous areas with upper and lower limbs

- UNI EN ISO 14119:2013 Safety of machinery Interlocking devices associated with guards,

- principles of design and selection

- CEI EN 60825-4 – Safety of laser equipment – Part 4 Laser barriers

- CEI EN 60825-4-A1 lasers – barriers

- CEI EN 60825-4-A2 lasers – barriers

SOUND-PROOFED SOUND-ABSORBING CABINS

To reduce the acoustic isolation of industrial machinery and plants, Accessafe Soundproof Cabins are designed and manufactured with modular soundproofing and sound-absorbing panels with the aim of ensuring sound pressure attenuation.

For each of our installations, it is possible to carry out a preliminary analysis of noise sources and their propagation towards operators or other machines. Once installation is complete, it is possible to verify the conformity of the results obtained by measuring the resulting sound pressure and comparing it with the customer’s preliminary requirements.

Accessafe designs soundproofing for the acoustic insulation of operator stations, machine tools, and systems of all sizes in any industrial context, thoroughly studying integration with the process functions of the machinery.

SCOPE OF APPLICATION

- Industrial machinery

- Production lines

- Suitable for all work environments

COMPATIBILITY

- HSRS high-speed doors

- Modular perimeter protection

- Access control systems

- Lighting

- Air conditioning

- Functional and safety control panels

REGULATIONS

- Machinery Directive 2006/42/EC

- Directive 2003/10/EC – on the minimum health and safety requirements regarding the exposure of workers to the risks arising from physical agents (noise)

- EN 1090-1: 2012 Execution of steel and aluminum structures

- UNI EN ISO 12100:2010 Safety of machinery – General principles for design – Risk assessment and risk reduction

- UNI EN ISO 14120:2015 General requirements for the design and construction of fixed and movable guards

- UNI EN ISO 13857:2008 Safety of machinery – Safety distances to prevent access to danger zones with upper and lower limbs

- UNI EN ISO 14119:2013 Safety of machinery – Interlocking devices associated with guards, principles for design and selection

- UNI EN ISO 11690-1:2021 – Acoustics – Practical recommendations for the design of low-noise work environments – Part 1

- UNI EN ISO 11203:2020 Acoustics – Noise emitted by machinery and equipment

- UNI EN ISO 3740:2019 – Acoustics – Determination of sound power levels of noise sources

- UNI 11347:2015 Acoustics – Workplace noise exposure reduction programs

- UNI EN ISO 11200:2020 – Acoustics – Noise emitted by machinery and equipment – Guidelines for use

OPERATOR CABINS CONTROL ROOM

Operator Cabins or Control Rooms are control stations where operators monitor and program production activities: they are designed to ensure optimal comfort and well-being for personnel.

The preliminary design phase takes into account functional requirements, safety requirements necessary for CE compliance of the machinery, and requirements related to the ergonomics of the solutions, so that the best possible results are achieved in terms of microclimate, visibility, and comfort for operators.

Through design that focuses on the needs of those who use them, it is possible to maintain high efficiency among personnel assigned to supervisory activities.

SCOPE OF APPLICATION

- Suitable for all work environments

COMPATIBILITY

- Modular perimeter protection systems

- Lighting

- Air conditioning

REGULATIONS

- Machinery Directive 2006/42/EC

- EN 1090-1: 2012 Execution of steel and aluminum structures

- UNI EN ISO 12100:2010 Safety of machinery – General principles for design – Risk assessment and risk reduction

- UNI EN ISO 14120:2015 General requirements for the design and construction of fixed and movable guards

- UNI EN ISO 13857:2008 Safety of machinery – Safety distances to prevent access to danger zones with upper and lower limbs

- UNI EN ISO 14119:2013 Safety of machinery – Interlocking devices associated with guards,

- principles of design and selection

- UNI EN ISO 11064-4:2014 – Ergonomic design of control centers – Part 4: Layout and dimensioning of workstations