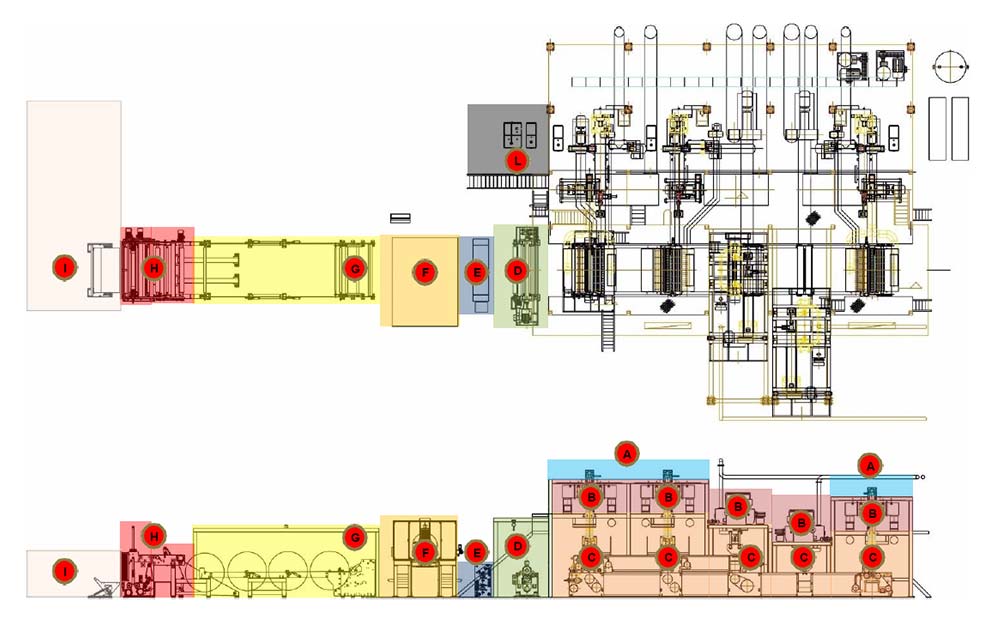

Perimetra Safety Design is the service we provide in designing all components and the appropriate logics for a later upgrade of the machinery according to current norms and regulations.

Perimetra provides a safety project according to prior risk evaluation including a 3D layout of guarding systems, electrical drawings, functioning logics and a list of implemented safety components with relevant technical sheets and maintenance schedule.

WE FOLLOW ALL STAGES OF THE PROJECT FROM RISK ANALYSIS TO SAFE PLANT COMMISSIONING.

PERIMETRA

MACHINERY DUE DILIGENCE

Documentation conformity check, audit at the client’s premises and drafting of the report which identifies obvious faults and suggest solutions for mitigation and an approximate budget.

PERIMETRA

RISK ASSESSMENT

Identification and analysis of hazards, risk assessment and definition of simplified or UNI EN ISO 12100 conformant mitigation measures.

PERIMETRA

SAFETY DESIGN

Design of safety components and safety logic systems required for upgrading, drawings, component list, maintenance schedule.

PERIMETRA

UPGRADING REMEDIATION

According to the safety design, technical intervention on the machinery to restore conformity and trial run.

PERIMETRA

CE MARKING PROCEDURE

Support in drafting and collecting all relevant documentation to achieve CE marking.

PERIMETRA

MACHINERY DUE DILIGENCE

Documentation conformity check, audit at the client’s premises and drafting of the report which identifies obvious faults and suggest solutions for mitigation and an approximate budget.

PERIMETRA

RISK ASSESSMENT

Identification and analysis of hazards, risk assessment and definition of simplified or UNI EN ISO 12100 conformant mitigation measures.

PERIMETRA

SAFETY DESIGN

Design of safety components and safety logic systems required for upgrading, drawings, component list, maintenance schedule.

PERIMETRA

UPGRADING REMEDIATION

According to the safety design, technical intervention on the machinery to restore conformity and trial run.

PERIMETRA

CE MARKING PROCEDURE

Support in drafting and collecting all relevant documentation to achieve CE marking.