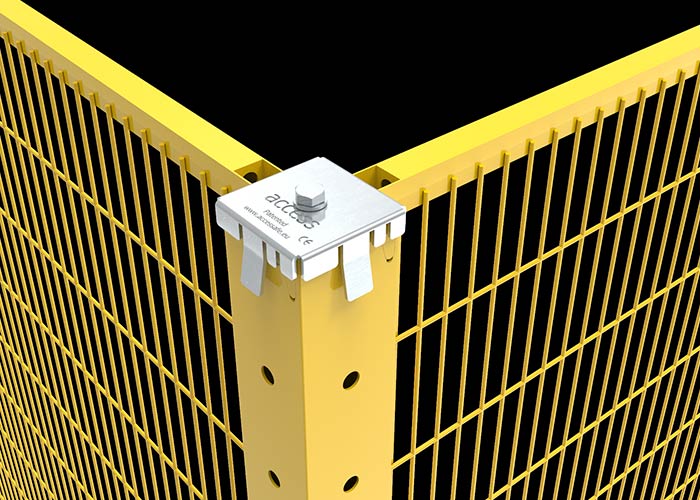

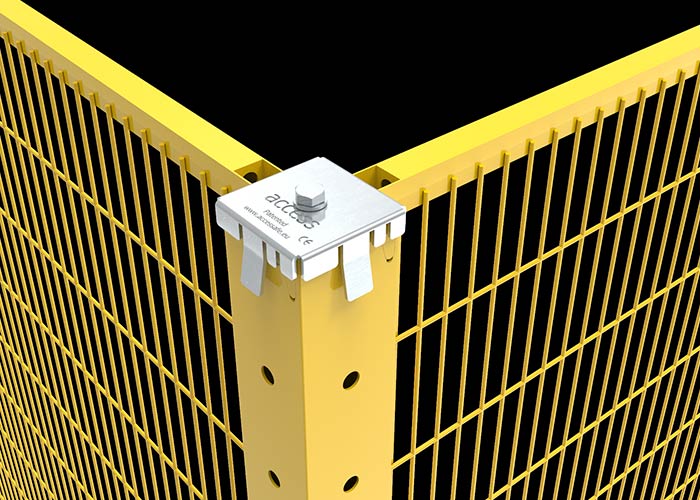

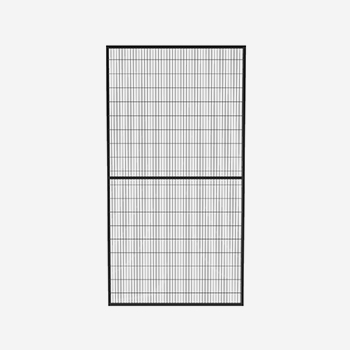

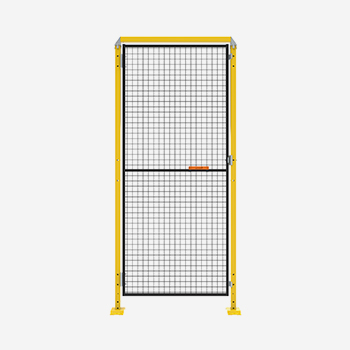

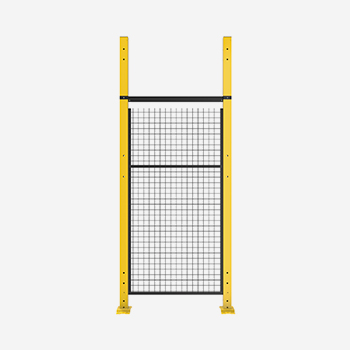

Accessafe framed or frameless steel safety guards are developed following three essential criteria: flexibility, quick installation, compliant with International standards UNI EN ISO 14120:2015, UNI EN ISO 13857:2008 and Machinery Directive 2006/42/CE.

Accessafe safety guards are manufactured to guarantee machinery and work area safety. They are manufactured with selected materials which guarantee the required safety standard and increase production efficiency.

All Accessafe machine guards are certified by a third body to conform with UNI EN ISO 14120:2015 standard and have passed the strictest impact tests.

WE WORK CONSTANTLY ON THE OPTIMISATION OF OUR SAFETY SOLUTIONS

AFTER SALES SERVICE

- MECHANIC ASSEMBLY

Full assistance during assembly operations of the safety guards and access point doors on-site.

- ELECTRIC INSTALLATION

Accessafe completes the safety solution with design and installation of the functional safety with safety switches, photoelectric barriers, radar and laser scanners controlled by safety management panels interconnected with production lines and machinery.

- PRE-ASSEMBLY

Assembly at our factory of doors, locking systems, pre-cabled electrical components ready for on-site installation which guarantees significant time saving.

- MAINTENANCE

On-site check of correct functioning of all safety components installed and planning of substitution guards and components which are no longer adequate.