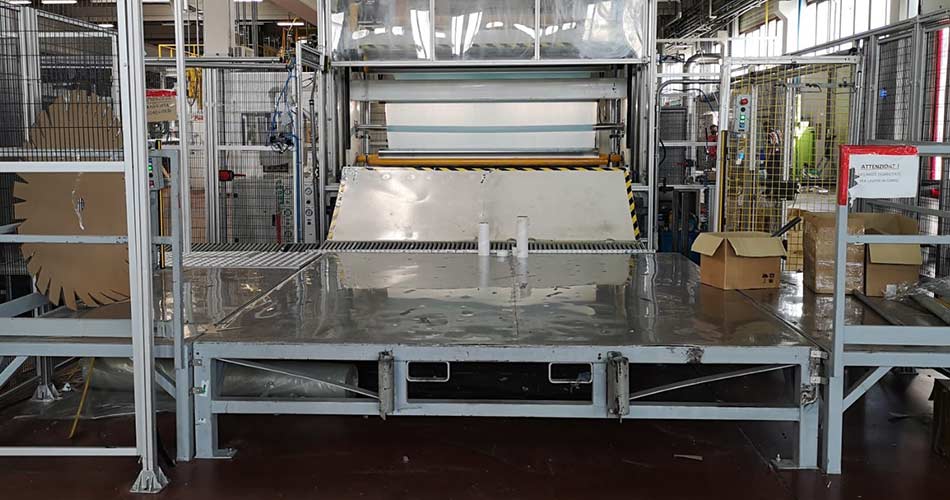

Industria Bergamasca Mobili S.p.A. , ISO 9001 and ISO TS16949 certified, works in the field of injection moulding of plastic materials and employs advanced technologies both in its moulding process (for example with RHCM) and in the automation of the production lines.

Accessafe was appointed the task to develop a project to guarantee the functional safety of 9 injection presses for thermoplastic moulds which had to include automation of unloading.

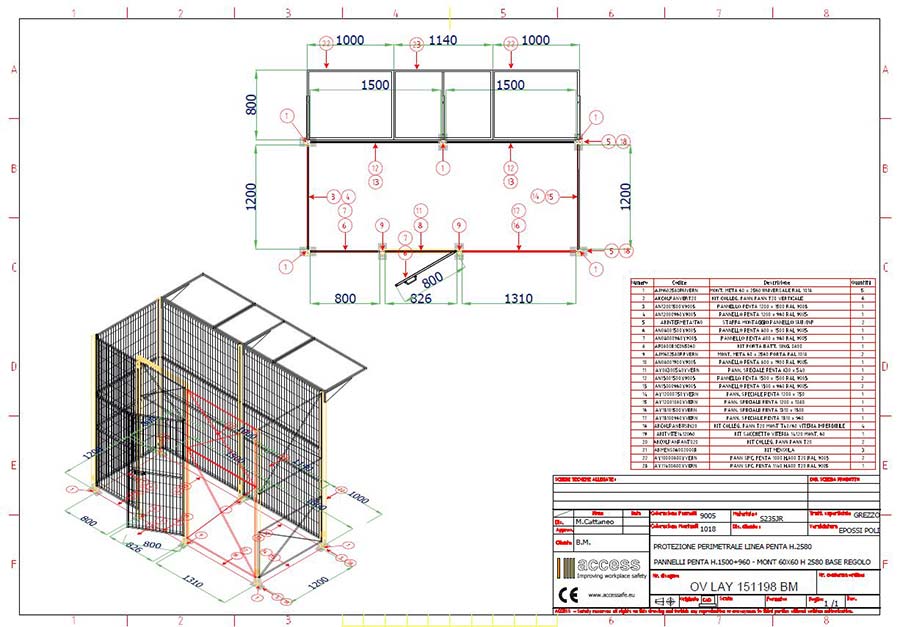

Once received the risk analysis drafted by the customer and the ESR (Essential Safety Requirements), Accessafe Engineers developed the protection layout in conformity with the harmonized standards which also included the project for access control for the acquired PLr as per specific standard requirement set by UNI EN ISO 13849:2016.

Accessafe delivered the entire turnkey project only 3 weeks after design approval:

Material

- Penta Guard Fencing System, 20 x 100 mm mesh ,2520 mm height combined with Meta 1 Fixing Brackets 60×60 mm section

- N.1 controlled access by means of a FG60 sensor in the Clo.Sys lock combined with a FR992 micro-switch in order to achieve PLd.

Mechanical component assembly

- Assembly of guard fencing panels and access control system

Laying and cabling of implemented parts

- Wire and cable sleeving, sensor connection and interfacing

- Control Electrical Cabinet

- N.1 signal light

Functional tests and documentation release

Upon installation termination, functional tests were carried out in the presence of plant manufacturer and BM SpA operators in order to release the following documentation:

- Certification

- User and Maintenance Manuals

- Technical Data Sheets and Electrical layouts

The above mentioned documentation was essential for the plant user to achieve CE marking for the complete line.

Executive design of the system

In-depth analysis by Marco Vaccarone CMSE® Certified Machinery Safety Expert follows below

«This project needed use to fence-off an automatic manipulator acting as a vacuum Pick-and-Place device at low speed, due to product fragility, of 250 mm/sec and 5 pcs/hour.