In the last two years, the application of robots in industrial processes has grown a lot mainly due to their versatility of use.

During this time, we have collaborated on machine projects in the traditional fields of automotive mechanics but also in areas generally defined as unusual such as the preparation of chemical-medical compounds and the processing of foodstuffs, always ensuring the highest level of efficiency and safety of perimeter guarding.

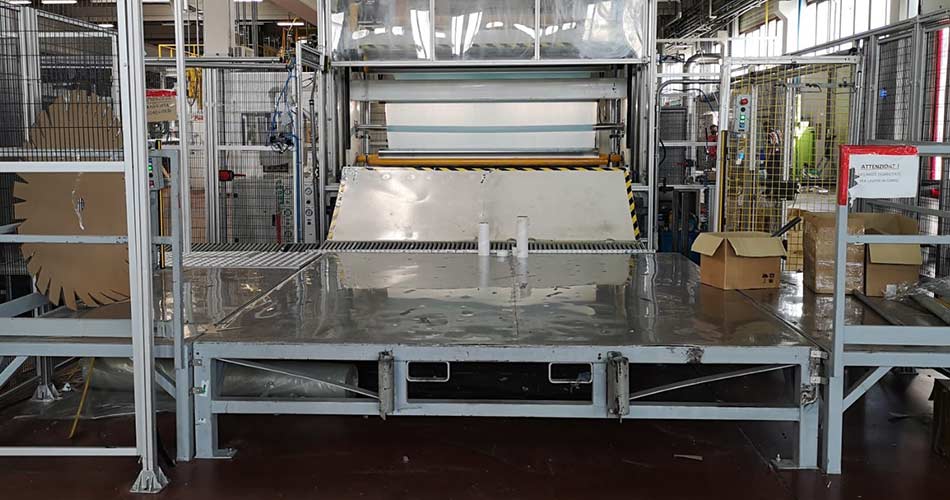

In this case, our customer, a robot integrator who has been active in the field of industrial automation for many years, needed to install an anthropomorphic product packaging robot in an environmentally certified factory with strict procedures.

In addition to the standard requirements necessary for CE certification:

type C UNI EN ISO 10218 Safety requirements for industrial robots – Part 2: Robot systems and integration

type B ISO 14123 Safety of machinery — Reduction of risks to health from hazardous substances emitted by machinery.

UNI EN 1672 Food processing machinery – Basic concepts – Part 2: Hygiene requirements

UNI EN ISO 953 Safety of machinery – Guards – General requirements for the design and construction of fixed and movable guards

UNI EN ISO 14119 Safety of machinery – Interlocking devices associated with guards – Principles for design and selection

UNI EN ISO 13857 Safety of machinery – Safety distances to prevent danger zones being reached by upper and lower limbs

Aesthetic and functional care was required, with particular reference to the ergonomic principles described in UNI EN ISO 12100.

We jointly selected the best AISI 304 austenitic steels and defined a welding specification at the highest possible level of finish with zero recovery of all TIG welds and subsequent manual satin-finishing of the joints, so that we can affirm the total absence of irregularities and dirty spots on the surfaces.

More than 40 hours of technical development were required to combine safety requirements with the customer’s aesthetic needs and around 300 hours of craftsmanship, a combination of technique and craftsmanship that is unparalleled in the industrial protection sector.