160 square meters of Accessafe perimeter protection for the safety of a piston production line.

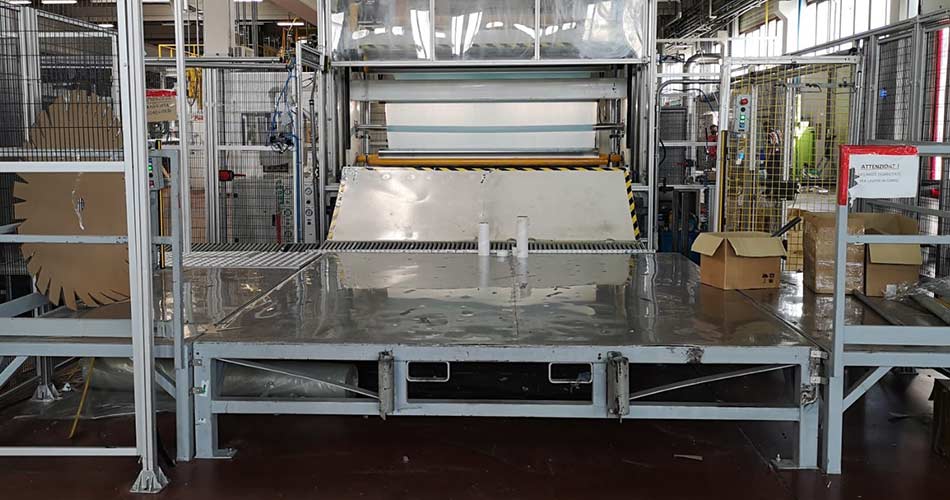

Work cycle starts with the melting of the alluminium alloy for the production of the rough parts which then shall be finished with elimination of eccess material and surface smoothing. In the following step pistons go through a quality control station which checks hundredth dimensional tolerance and then parts are allocated to specific containers for handling operations.

Operations are carried out by 4 Fanuc robots which cater for parts handling to and from working stations (2 100 kg load at the wrist for casting and unloading and 2 165 kg load at the wrist for cutting and measuring).

After analyzing the technical specifications and requirements relating to the plant’s target working environment, Accessafe’s technical department asked the customer to indicate their preferences regarding the machine’s functional specifications, the geometry of the guards, the colors, and the interlocking systems associated with the guards.

Accessafe followed the working methodology of Machinery Directive 42/2006, incorporating the risk analysis and RES relating to perimeter protection, and verified its compatibility with regulatory requirements, starting with type C standards and continuing with type B standards:

- Type C Standard UNI EN ISO 10218: Safety Requirements for Industrial Robots

- Type B Standard UNI EN ISO 12100: Safety of machinery, General principles for design

- Type B Standard UNI EN ISO 14120: General requirements for the design and construction of guards

- Type B Standard UNI EN ISO 13857: Safety distances to prevent hazard zones being reached by upper and lower limbs

- Type B Standard UNI EN ISO 13849: Safety-related parts of machinery control systems

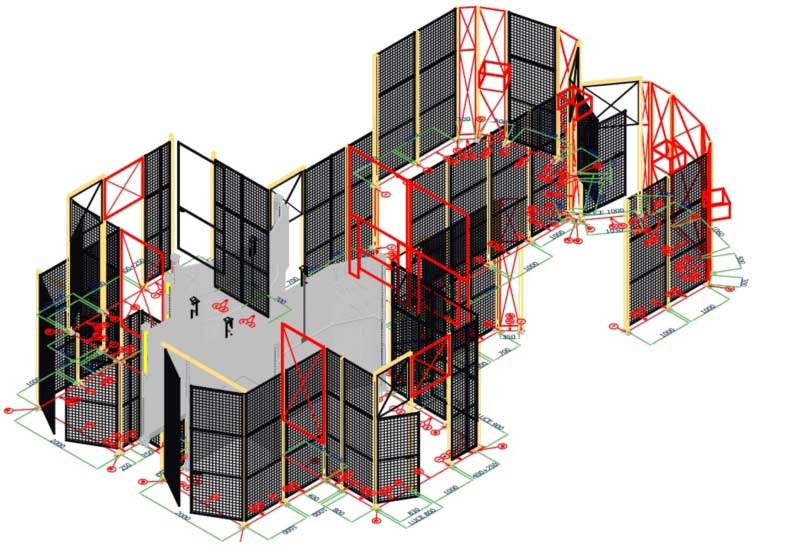

The project design is entirely customised as it can rely only on a limited number of standard parts due to risks deriving from handling speed and potential part expulsion from within the working area along with the need to keep some semi-free areas for loading/unloading operations.

The design was submitted to the customer for approval after being processed using Accessafe’s proprietary software, which allows the functionality of the protection to be verified thanks to 3D visualization showing the components of the mobile guards, their speed and opening stroke, as well as the final appearance of the cell as it will look when installed.

To achieve the required height, Linea Quadra overlapping panel perimeter protection was used with the aid of Accessafe connection kits combined with the Meta 1 captive fastening system, height 3 meters, section 60×60, DBS welded base, and deformation resistance in accordance with UNI EN ISO 14120.

The solution studied for the loading/unloading semi-free areas was to implement 4 special pneumatic doors with vertical opening conformant to UNI EN ISO 13849 and Performance Level D with the following characteristics:

- Door panel size 80 x 60 mm “L” and “C” shape

- Central pneumatic cylinder

- Safety counterweights

- Ball bearing rail guards

- Double polycarbonate panels with anti-phalanx mesh

- Limit switches

- Stroke control proximity switch

- Safety Sensitive edges

- Safety device for signal management

- Doors are supplied with a declaration of incorporation, technical booklet with use and maintenance instructions in the language of system’s country of destination, in this case Spanish.

Customer’s comment upon completing installation:

GFS Gravity srl has been working with Accessafe for years to supply fixed and mobile guards for installation on its casting lines.

Custom solutions, rapid response and modification even during ongoing projects, and the robustness and reliability of the solutions offered have made Accessafe our partner of choice in this field. In particular, for our upcoming installation in Mexico, the vertical sliding doors installed have allowed us to provide a highly flexible cell (with the possibility of excluding one machine from the cycle while continuing to work on the other) in compliance with the safety requirements of the latest regulations.»