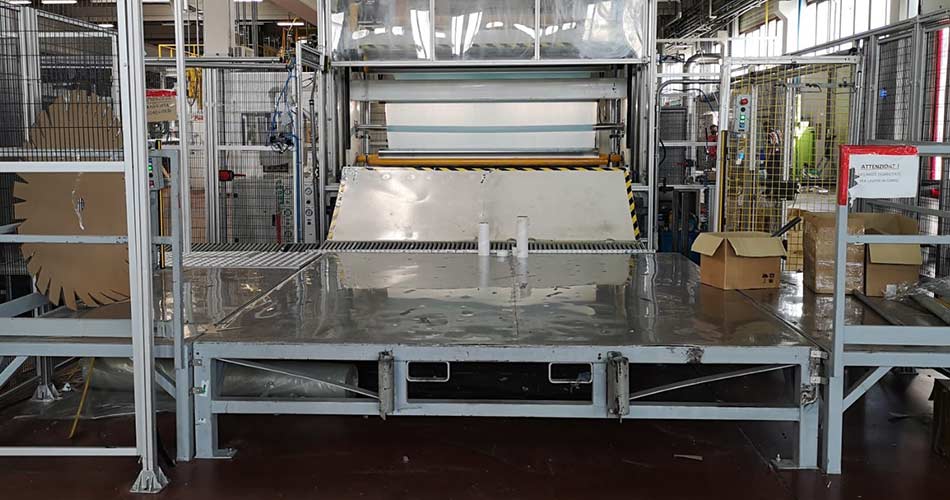

Industria Bergamasca Mobili S.p.A. , ISO 9001 and ISO TS16949 certified, works in the field of injection moulding of plastic materials and employs advanced technologies both in its moulding process (for example with RHCM) and in the automation of the production lines.

Accessafe ha ricevuto l’incarico di sviluppare il progetto per la messa in sicurezza di 9 presse ad iniezione per stampi termoplastici con relativa automazione di scarico.

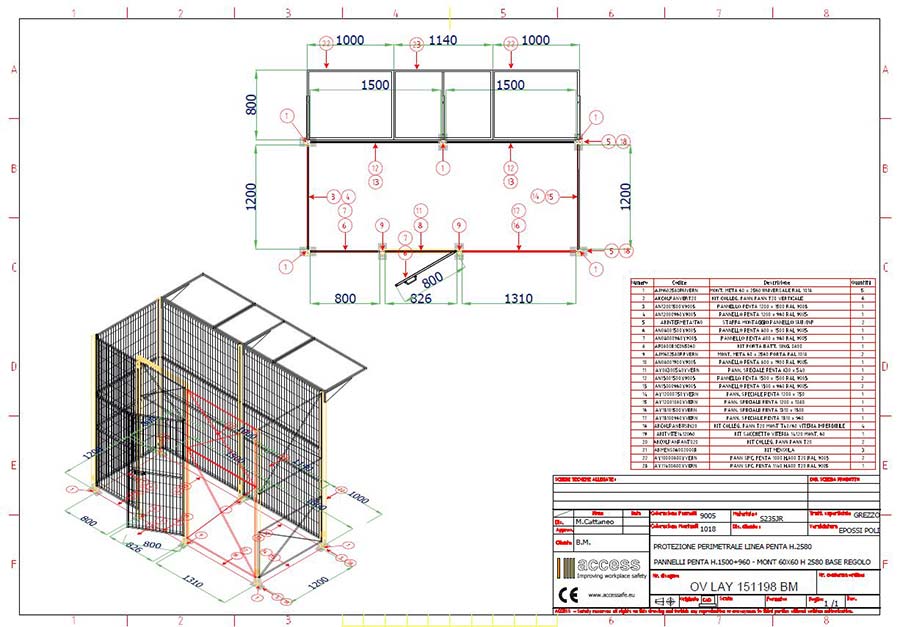

Dopo aver recepito l’analisi rischi preparata dal cliente e i RES (Requisiti Essenziali di Sicurezza), i tecnici Accessafe hanno sviluppato il layout delle protezioni in conformità alle norme amonizzate incluso il progetto di controllo degli accessi secondo il PLr acquisito come da specifica normativa UNI EN ISO 13849:2016.

In sole 3 settimane dalla data di approvazione dei prospetti tecnici, Accessafe ha fornito il progetto completo chiavi in mano:

Material

Penta Guard Fencing System, 20 x 100 mm mesh ,2520 mm height combined with Meta 1 Fixing Brackets 60×60 mm section

- N.1 controlled access by means of a FG60 sensor in the Clo.Sys lock combined with a FR992 micro-switch in order to achieve PLd.

- Assembly of guard fencing panels and access control system

Laying and cabling of implemented parts

- Wire and cable sleeving, sensor connection and interfacing

- Control Electrical Cabinet

- N.1 signal light

Functional tests and documentation release

Upon installation termination, functional tests were carried out in the presence of plant manufacturer and BM SpA operators in order to release the following documentation:

- Certification

- User and Maintenance Manuals

Technical Data Sheets and Electrical layouts

The above mentioned documentation was essential for the plant user to achieve CE marking for the complete line.

Electro-locking system with access request management

Falling parts prevention protection system in operator area

Penta guard fencing 20×100 mesh

Meta 1 fixing brackets 60×60 section with captive screw as per EN ISO 14120

Executive design of the system

In-depth analysis by Marco Vaccarone

CMSE® Certified Machinery Safety Expert follows below